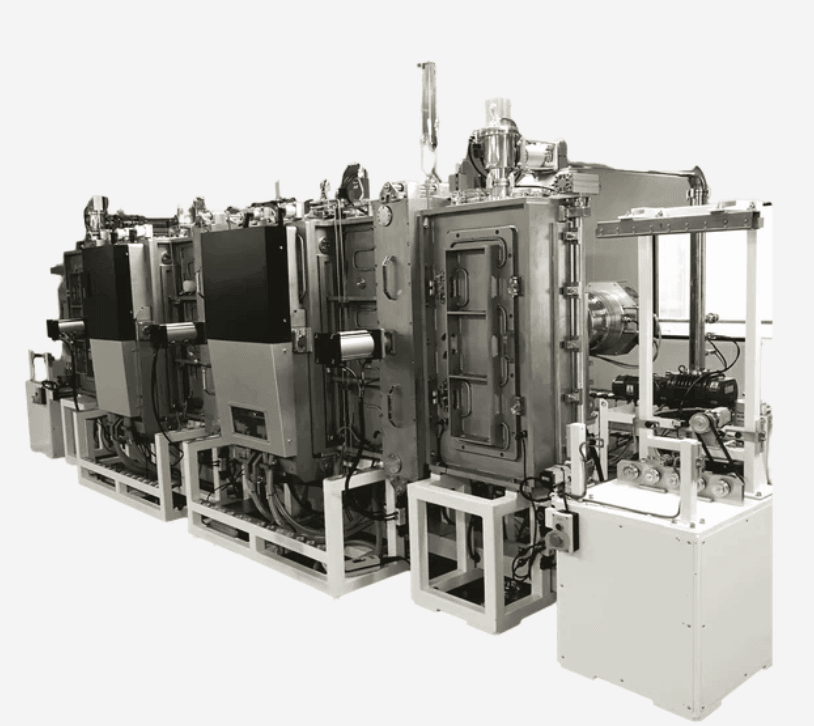

Solar Magnetron Sputtering Equipment for Perovskite Thin Film Coating

Solar Magnetron Sputtering Equipment for Perovskite Thin Film Coating

SIMVACO magnetron sputtering equipment is designed for precision thin-film deposition of perovskite materials, widely used in advanced solar cell manufacturing. This system delivers high-efficiency and uniform coatings, enabling consistent layer quality essential for improving energy conversion in perovskite solar cells.

Key Features

- Precision Magnetron Sputtering: Ensures controlled and uniform deposition of perovskite thin films with optimized layer thickness and material density.

- Large Substrate Compatibility: Handles substrates up to 600×600 mm, supporting R&D and pilot-scale production for solar cell manufacturing.

- Stable Vacuum Performance: Achieves vacuum levels of ≤1×10⁻⁴ Pa, ensuring a clean process environment that minimizes contamination and defects.

- Real-Time Process Monitoring: Integrated systems track film thickness, deposition rate, and vacuum stability for repeatable and precise results.

- Multi-Layer Deposition: Supports the creation of multi-stack thin-film structures critical for efficient perovskite solar cell production.

- Substrate Heating Control: Adjustable heating up to 350°C enhances film crystallization and adhesion, improving overall solar cell performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Deposition Technology | Magnetron Sputtering |

| Coating Material | Perovskite, Conductive Oxides, Metals |

| Substrate Size | Up to 600×600 mm |

| Vacuum Pressure | ≤1×10⁻⁴ Pa |

| Coating Uniformity | ±1% |

| Film Thickness Range | 10nm - 500nm |

| Deposition Speed | Up to 5nm/s |

| Substrate Heating | Up to 350°C |

| Process Control | Real-time thickness and vacuum monitoring |

Applications

- Perovskite Solar Cells: Uniform and stable thin-film deposition for improving solar energy conversion efficiency.

- Multi-Layer Solar Coatings: Deposition of conductive and functional layers required for advanced solar cell architectures.

- Research and Development: Ideal for perovskite material testing, prototyping, and pilot-scale production.

- Optoelectronic Devices: Thin-film coatings for sensors, flexible displays, and related optoelectronic components.

Process Advantages

- High Uniformity: Delivers consistent coating thickness and material properties across the entire substrate surface.

- Scalable Production: Designed for large substrates, ensuring adaptability from laboratory to pilot-scale manufacturing.

- Precision Control: Real-time monitoring systems ensure accuracy and repeatability for complex multi-layer thin films.

- Material Efficiency: Optimized sputtering processes minimize target material waste and enhance deposition performance.

Our magnetron sputtering equipment for perovskite coating represents advanced technology for high-precision deposition critical to next-generation solar cell manufacturing. With stable vacuum performance, substrate heating, and multi-layer capability, it meets the demands of research and industrial applications focused on improving solar efficiency. For more information or to request a demonstration, please contact us today!

Share