1

/

of

1

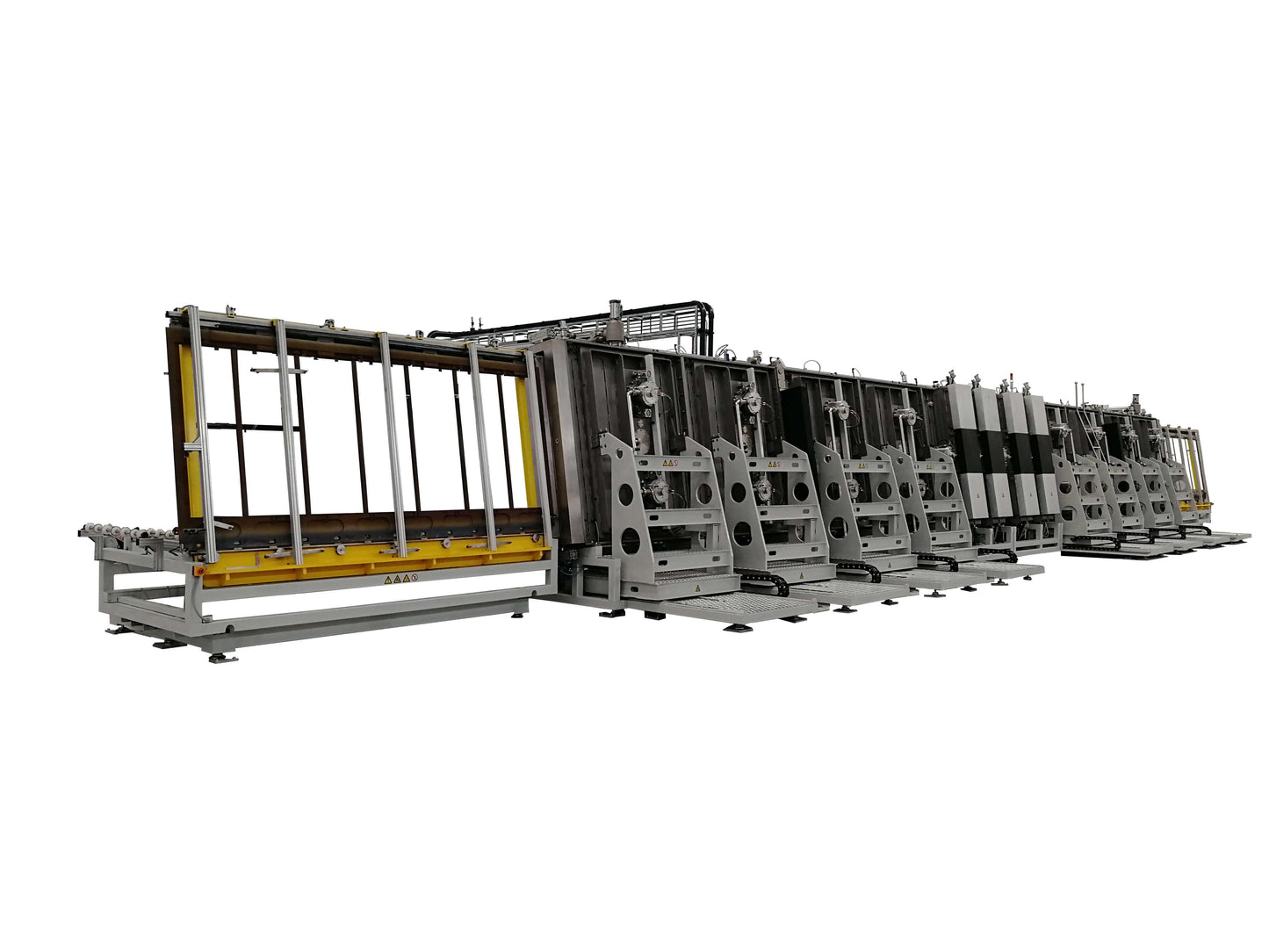

Large-Area Multi-Arc Ion Decorative Coating Machine for Metal Surfaces

Large-Area Multi-Arc Ion Decorative Coating Machine for Metal Surfaces

Our Decorative Large-Area Multi-Arc Ion Coating Equipment is specifically designed for high-quality coating of metal surfaces, including stainless steel. This inline system offers advanced features that ensure efficient and uniform deposition, making it ideal for decorative applications in various industries.

Key Features

Inline Multi-Arc Ion Coating Technology

- Continuous Coating Capability: Enables high-efficiency roll-to-roll processing for uninterrupted substrate movement and optimized throughput.

- High-Precision Ion Deposition: Ensures consistent coatings with excellent adhesion across large stainless steel surfaces.

- Advanced Plasma Control: Maintains stable ionization for precise material deposition, reducing defects and improving coating quality.

- Material Versatility: Compatible with metals, alloys, and compound coatings to produce a variety of colors, finishes, and functionalities.

- Durable and Aesthetic Coatings: Creates hard, scratch-resistant surfaces with premium visual appeal, tailored for decorative purposes.

Optimized for Decorative Metal Coatings

- Customizable Coating Recipes: Offers tailored solutions for achieving gold, chrome, titanium, and other finishes.

- Scalable for Large Substrates: Designed for large-area metal sheets or rolls, ensuring efficient production for continuous operations.

- Eco-Friendly and Sustainable: Utilizes energy-efficient processes and advanced vacuum systems to minimize waste and reduce environmental impact.

Advanced Automation and Vacuum Systems

- Ultra-High Vacuum: Operates at 10⁻³ to 10⁻⁴ Torr to ensure clean, high-quality coatings free from contamination.

- Intelligent Automation: Fully automated loading, coating, and unloading processes reduce labor requirements and ensure consistent quality.

- Precision Monitoring: Real-time diagnostics and in-situ monitoring enhance process control and coating uniformity.

- Energy-Efficient Design: Reduces operational costs while maintaining superior coating performance.

Applications

- Architectural Metal Panels: Durable and decorative finishes for doors, facades, and interior fixtures.

- Functional Coatings: Provides hard coatings that enhance wear resistance and corrosion protection, suitable for tools and industrial components.

- Automotive Components: Coatings for trims, emblems, and grilles with premium aesthetic quality.

- Customizable Color Options: Capable of applying a wide range of colors and finishes, including titanium gold, rose gold, champagne gold, and various shades of black and silver.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Inline Multi-Arc Ion Coating System |

| Substrate Type | Stainless Steel and Other Metals |

| Vacuum Chamber Size | Customizable up to 1500×1500×2000 mm |

| Ultimate Vacuum | ≤1×10^-4 Pa |

| Arc Power Supply | Adjustable up to 100 kW |

| Substrate Heating Temperature | Up to 500°C ± 5°C |

| Substrate Speed | Continuous, adjustable for inline processing |

| Coating Thickness Control | In-situ monitoring with high precision |

Advantages

- Seamless Production: Inline design enables continuous processing, reducing downtime and maximizing efficiency.

- Exceptional Durability: Coatings resist wear, scratches, and corrosion, ensuring long-lasting performance.

- Aesthetic Versatility: Wide range of customizable finishes for premium decorative applications.

- High Throughput: Optimized for large-scale production with consistent quality.

- Environmentally Friendly: Advanced vacuum technology reduces waste and energy consumption.

The Decorative Large-Area Multi-Arc Ion Coating Equipment represents the pinnacle of surface coating technology. With its impressive technical specifications and versatile applications, it is the perfect solution for industries seeking high-quality coatings on metal surfaces. For further information or to request a demonstration, please contact us today!

Share