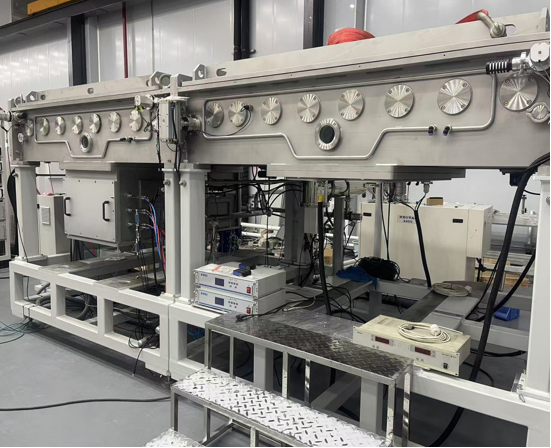

SIMVACO Triple-Source Co-Evaporation System for Perovskite Thin Film Research

SIMVACO Triple-Source Co-Evaporation System for Perovskite Thin Film Research

Product Overview

The SIMVACO Triple-Source Co-Evaporation System is a high-precision vacuum deposition platform designed for advanced perovskite thin film research and small-scale device development. By independently controlling three evaporation sources, the system enables precise co-deposition of multi-component perovskite materials, addressing common challenges such as composition imbalance, crystal defects, and film instability during conventional thermal evaporation.

This system is ideal for academic laboratories, research institutions, and R&D facilities working on MAPbI₃, FAPbI₃, or mixed-cation perovskite thin films for solar cells and optoelectronic applications.

Key Advantages

1. Independent Triple-Source Control

- Each evaporation source is fully independent, allowing precise control over the deposition rates of organic cations (MAI/FAI), metal halides (PbI₂/PbBr₂), and optional auxiliary components.

- Ensures stoichiometric film formation, reducing pinholes, defects, and non-ideal phases.

2. High Vacuum and Controlled Environment

- Achieves vacuum levels of 10⁻⁶–10⁻⁷ Torr, minimizing contamination from volatile by-products and atmospheric moisture.

- Integrated inert gas and drying protection preserves organic components and enhances film stability.

3. Optimized Film Uniformity and Crystallinity

- Precise control of substrate temperature, rotation, and vapor distribution ensures uniform deposition across large substrates.

- Enables control over nucleation density and crystal grain size, improving optoelectronic performance.

4. Flexible Research and Development

- Supports various perovskite compositions, including mixed cation and halide systems (MA⁺, FA⁺, Cs⁺, Rb⁺, I⁻, Br⁻).

- Adjustable process parameters allow rapid optimization for research and small-batch production.

5. Smart Monitoring and Data Recording

- Equipped with high-precision Quartz Crystal Microbalance (QCM) for real-time evaporation rate monitoring.

- Enables reproducible experiments with data logging and process replay for process optimization.

Technical Specifications (Reference)

| Parameter | Specification |

|---|---|

| Vacuum Level | ≤ 5×10⁻⁷ Torr |

| Number of Sources | 3 independent sources (organic, metal, auxiliary) |

| Source Temperature Range | 20–350 ℃, individually controlled |

| Substrate Heating | Room temperature to 200 ℃, rotation or static |

| Evaporation Rate | 0.01–10 Å/s, ±2% accuracy |

| Control System | Touchscreen + PC, QCM real-time monitoring |

| Compatible Substrates | Glass, ITO, silicon, flexible substrates |

| System Footprint | Customized for lab or research bench use |

Applications

- Perovskite Solar Cell Research: Thin film development, efficiency optimization

- Mixed-Cation Perovskite Studies: Precise multi-component film formation

- Functional Thin Film Development: Photodetectors, optoelectronics, flexible electronics

- Process Optimization Research: Component ratio, deposition rate, crystallization studies

Why Choose SIMVACO

- Over 15 years of experience in vacuum coating and deposition technology

- Advanced triple-source co-evaporation solution addressing perovskite thin film challenges

- High precision, reproducible, and research-friendly system

- Globally validated by research institutions and industry R&D labs

Contact Information

For detailed product information, custom configurations, or technical support:

Email: simon@simvaco.com

WhatsApp / Phone: +86-15958205967

Website: https://simvaco.com

Share