Advanced Evaporation Coating Equipment for Automotive Lighting SIMVACO

Advanced Evaporation Coating Equipment for Automotive Lighting SIMVACO

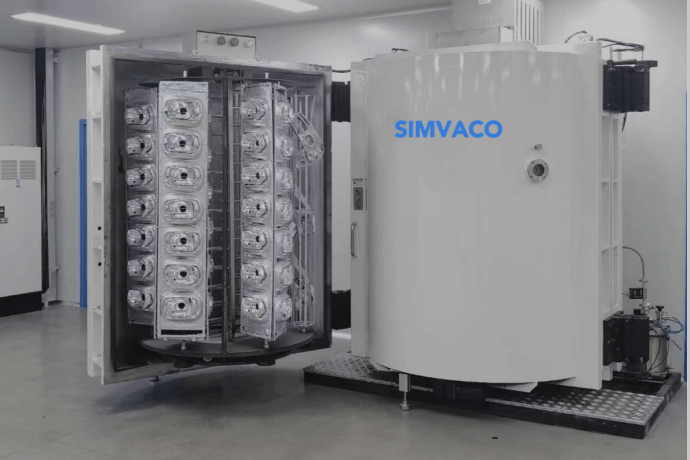

SIMVACO’s Automotive Lighting Coating Equipment is a cutting-edge solution designed to meet the evolving needs of the automotive lighting industry. Combining advanced Plasma Pre-treatment Technology with a high-performance Silicone Oil System, this equipment enhances the durability, adhesion, and visual quality of automotive lighting components. By leveraging state-of-the-art PVD (Physical Vapor Deposition) technology, the system ensures superior coatings that offer UV protection, scratch resistance, and corrosion resistance, all while optimizing operational efficiency and sustainability. With these innovations, SIMVACO provides a reliable and versatile solution for automotive lighting manufacturers seeking enhanced performance, aesthetics, and environmental compliance.

Key Features and Technologies

Plasma Pre-treatment Technology

Plasma pre-treatment is a vital process for improving coating adhesion and uniformity. By using low-temperature plasma to clean and activate the surface of automotive light components, the system ensures optimal coating adhesion and longevity.

- Improved Coating Adhesion: Increases surface energy for strong and lasting bonding between coatings and substrates.

- Effective Surface Cleaning: Removes oils, dust, and other contaminants, creating a clean substrate for a defect-free coating.

- Eco-Friendly Process: Plasma treatment eliminates the need for chemicals, reducing environmental impact while improving efficiency.

Silicone Oil System

The Silicone Oil System significantly enhances the aesthetics and durability of coated automotive lighting components. By applying a thin, even layer of silicone oil, it adds an additional layer of protection and shine.

- Enhanced Gloss and Smoothness: Achieves a mirror-like finish that enhances the visual appeal of automotive lights.

- Increased Durability: Provides additional scratch resistance, UV protection, and weather resistance, extending the lifespan of the lighting components.

- Uniform Application: Ensures even distribution of the silicone oil, preventing gloss inconsistencies and streaks.

Advanced Coating Uniformity

SIMVACO’s equipment ensures a highly uniform coating, which is critical for optical applications like automotive lighting. The consistency in coating thickness is key to achieving optimal light reflection and aesthetic appeal.

- Consistent Coating Thickness: Ensures a uniform and precise coating layer, critical for the functionality of automotive lighting.

- Uniform Coverage: Achieves consistent application across all components, reducing defects and minimizing rework.

High-Efficiency Coating Process

Designed for energy efficiency, the coating system reduces operational costs while maintaining superior performance. Its streamlined design accelerates the production cycle without compromising the quality of the coating.

- Energy-Efficient Operation: Low power consumption ensures that the equipment delivers cost savings without sacrificing performance.

- Faster Turnaround: The quick processing times help increase manufacturing throughput, making the system ideal for high-volume production.

Environmental and Sustainability Benefits

As the automotive industry increasingly emphasizes sustainability, SIMVACO’s equipment integrates eco-friendly features that minimize the environmental footprint.

- Reduced Chemical Waste: The plasma pre-treatment process is chemical-free, reducing the need for hazardous materials and making it safer for workers.

- Energy Savings: The efficient system consumes less energy, helping manufacturers reduce their carbon footprint and comply with environmental regulations.

Customizable Coating Solutions

The system is highly adaptable, offering flexibility to meet the specific needs of various automotive lighting applications. Whether you need a standard finish or a custom aesthetic, SIMVACO’s equipment can deliver precise, tailored results.

- Versatility in Materials: Handles a wide range of materials such as aluminum, nickel, and titanium, accommodating various coating requirements.

- Adjustable Coating Thickness: The ability to fine-tune coating thickness ensures that it meets the specific optical and functional needs of different automotive lighting components.

Automated Control and Monitoring

With automated PLC controls and a user-friendly touchscreen interface, the system allows manufacturers to efficiently manage and monitor the coating process.

- Real-Time Data Monitoring: Operators can track performance and make adjustments instantly to ensure optimal production outcomes.

- Seamless Integration: The system can be easily integrated into existing production lines, ensuring a smooth transition and minimal downtime.

Why Choose SIMVACO’s Automotive Lighting Coating Equipment?

SIMVACO’s coating equipment offers exceptional performance in key areas such as adhesion, durability, and aesthetic finish. The Plasma Pre-treatment and Silicone Oil System work in tandem to ensure that automotive lighting components maintain their quality even under challenging conditions. The system is designed to help manufacturers achieve high-quality results with lower environmental impact, improved operational efficiency, and faster production cycles.

Industry Insights and Trends

The global automotive lighting market is projected to reach $37.2 billion by 2026, with a 6.7% CAGR from 2021. With the increasing shift toward LED technology, particularly in adaptive lighting systems, manufacturers are in need of high-quality coatings that enhance optical properties and ensure long-lasting durability. Sustainability is also a driving force, with companies adopting eco-friendly production processes to meet environmental regulations. SIMVACO’s equipment addresses both of these trends by offering advanced coating technologies that reduce chemical use, improve energy efficiency, and produce durable, high-quality finishes.

Applications

- Automotive Headlights & Taillights: Improve brightness, light output, and durability, ensuring long-lasting performance under extreme conditions.

- Exterior Lighting Components: Enhance resistance to UV degradation, weathering, and other environmental factors.

- Custom Lighting Finishes: Achieve unique finishes and aesthetic effects for premium automotive lighting solutions.

Conclusion

SIMVACO’s Automotive Lighting Coating Equipment integrates Plasma Pre-treatment Technology and a Silicone Oil System to offer superior adhesion, durability, and aesthetic finishes for automotive lighting. By enhancing performance, energy efficiency, and sustainability, SIMVACO’s equipment helps manufacturers stay competitive in an increasingly demanding market. Whether you're looking for high-volume production or custom coatings, SIMVACO provides a reliable, eco-friendly solution to meet your needs.

Get in Touch with SIMVACO

For more information or to discuss your specific coating requirements for automotive lighting, contact us:

- Website: https://simvaco.com

- Email: simon@simvaco.com

- WhatsApp: +86-15958205967

Share